You Design it, We Make it - Read more about our technical specifications

Chemical Etching

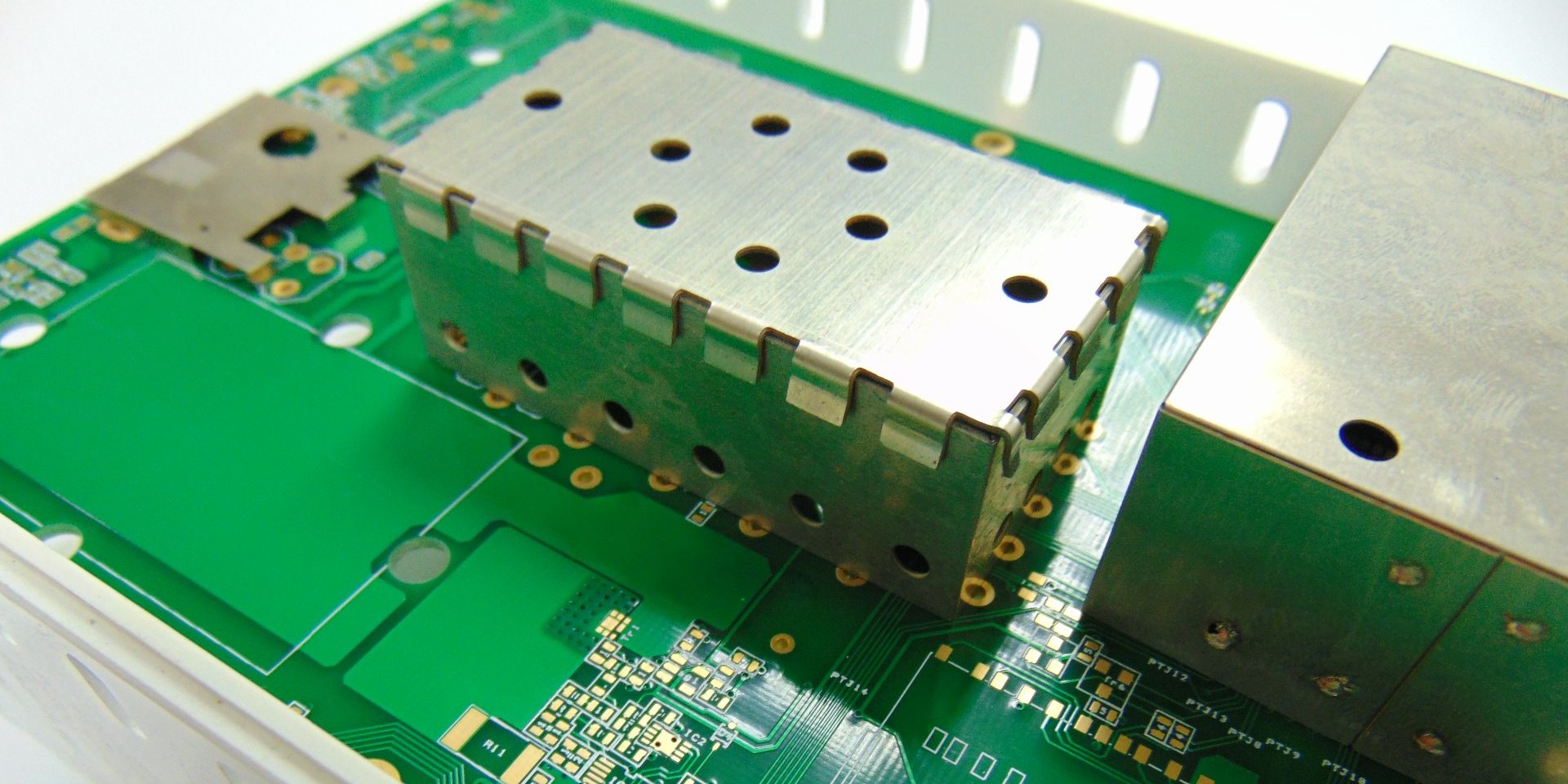

Our Chemical Etching process is used to produce thin (up to 3mm thick) metal components in a variety of ferrous and non-ferrous metals.

These metal components (which previously would have been manufactured by conventional machining or blanking operations) are produced using acid etching (photochemical blanking) to dissolve away the unwanted material, leaving you with the exact shape and size of your finished components.

The Chemical Etching (also known as photo fabrication, or Chemical Milling) process allows surface detail to be etched into one or both sides of the component at the same time.

To find out more about our Photo Etching Process please either contact our customer accounts team now

Advantages over conventional milling

Low cost

Fast production times (standard lead time 5 working days)

No burnt edges, or processing residue (dross)

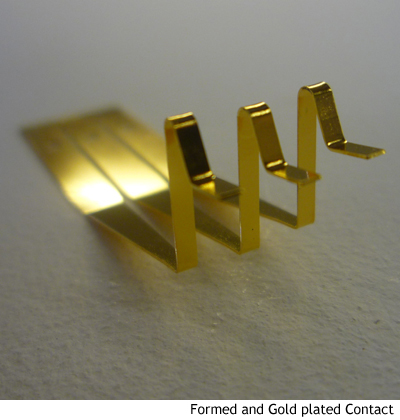

Half-etched fold lines for part marking and cost effective forming

Apertures can be on both sides as the etchant works on both sides of the metal for the same cost

Resulting etched metal is burr, & stress, free

Fast, scalable, metal component prototyping

Components are etched to a high level of precision

Low cost graphic tooling

Scalable through short-run to high volume

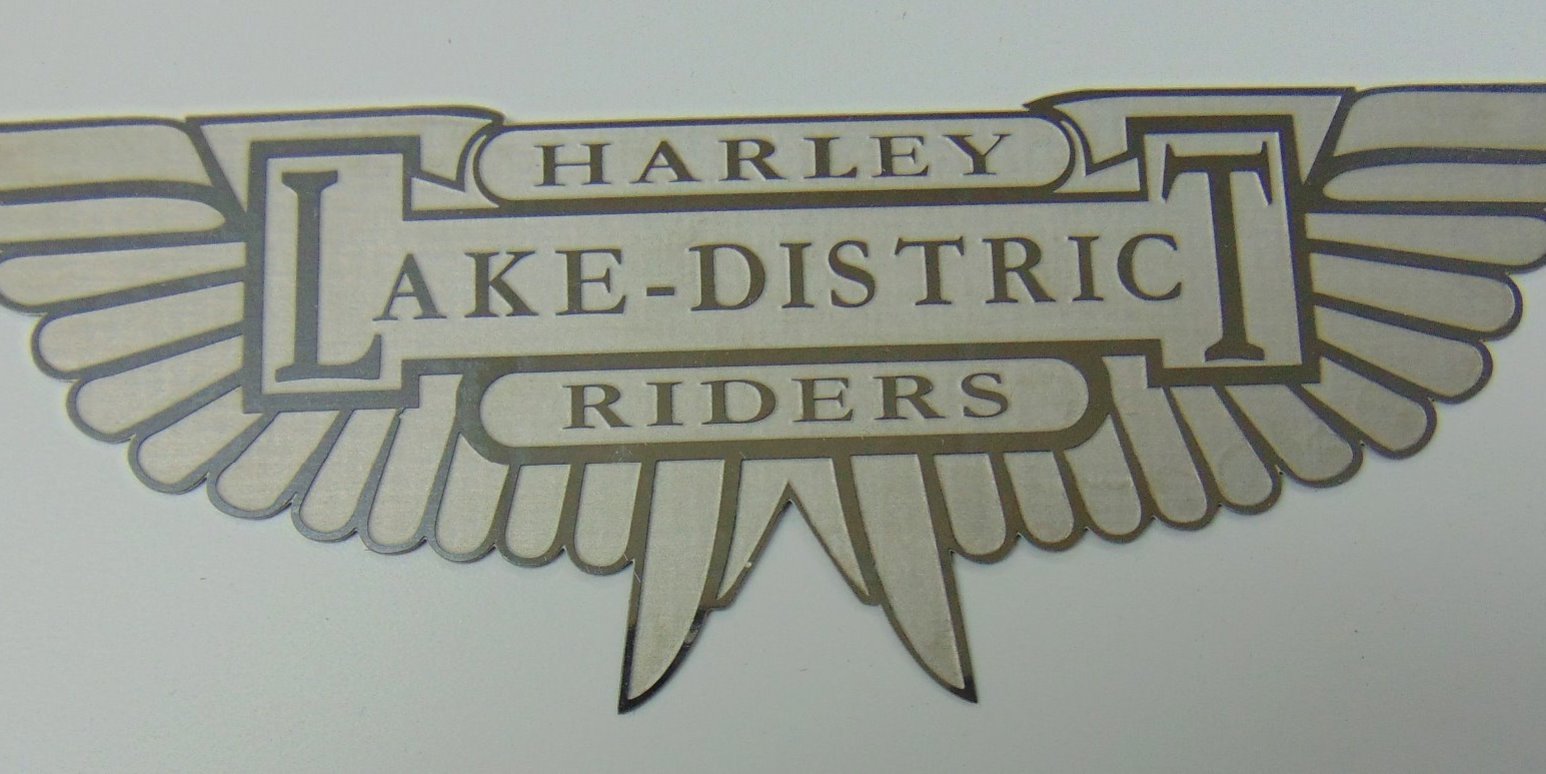

Custom parts - You design it - We make it!

Large panel etching capability

Why Chemical Etching is Right for You:

At Etch Tech our experience means the possibilities are huge!

Chemical Etching is the ideal process to produce complex shapes, because there are no additional processing costs for even the most complex of profiles or complicated hole arrays.

Tooling consists of a set of precision photographic negatives, produced on the industries’ best design and drafting programs. Once drawn and QA approved, they are stored on our dedicated server and available for printing at any time. As well as being very efficient, you can modify your component at any time, without expensive tooling modification charges. Unlike hard tooling methods, the existing tooling does not have to be decommissioned in order to make modifications. Your production schedule is not at risk in any way whilst your modifications are implemented.

Part Marking and Low Cost Forming options

The Chemical Etching process allows surface detail to be etched into one or both sides of the component at the time of manufacture. Your company logo, part numbers, address or even a picture can be permanently etched at your desired location. The same technique is utilised to accurately inscribe lines on the surface to allow parts to be hand folded without the need for form tooling, a process which is widely used to form EMI/RFI screening cans.

Get a Fast Track Quote

Tell us about your photo chemical etching requirements today and get a fast track quote. We aim to respond to requests within 4 hours of receipt of your contact, 24 hours guaranteed!