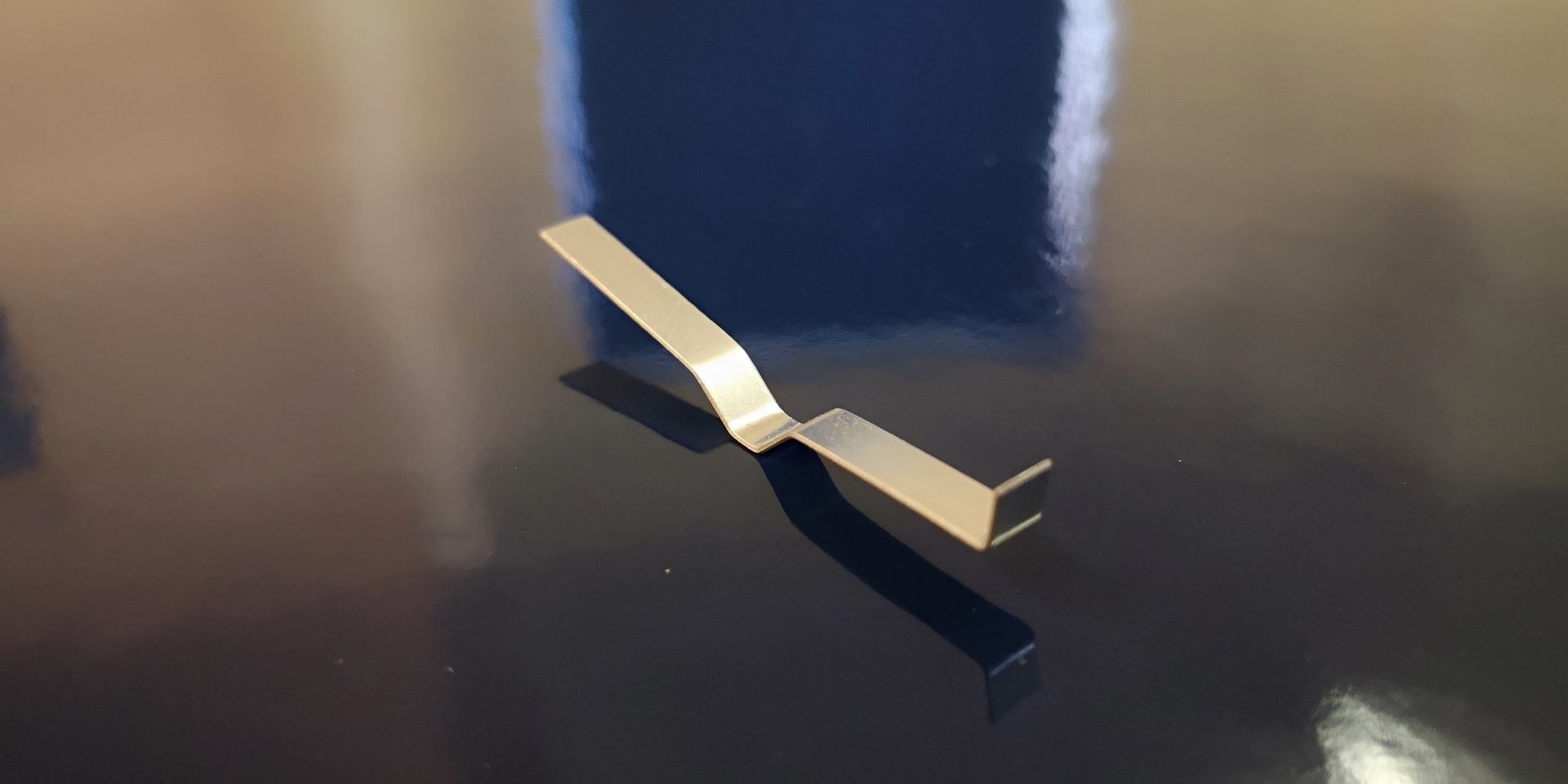

As well as the rapid and flexible solution Etch-tech provides for your flat precision components, you can take advantage of our expertise in manufacturing 3D (formed) parts.

Half-etched fold lines or hard-formed bends

Having the choice between half etched fold lines or hard formed bends gives you the flexibility no other process can offer. If half etched bend lines are not suitable for your application we often offer fully formed parts utilising form tools from our extensive tool library, thereby reducing your non recurring charges.

Low cost, high quality tooling

On occasions when suitable tooling is not available we would be pleased to quote for job specific tools manufactured in our onsite tool room, at a fraction of the cost of complex progression tools. Etch Tech’s large investment in a tool room and fly presses has enabled us to offer low cost, high quality tooling in short lead times to our customers.

Experienced Toolmakers at Etch Tech

Our toolmakers have extensive experience in forming all types and tempers of metals including spring temper stainless steel allowing you complete freedom of design. We now offer 3D printed tools manufactured in house by our dedicated graphics team. This results in shorter lead times and cheaper tooling costs on forming jobs.

Fully equipped Tool Room at Etch Tech

As Etch Tech has invested in both a Tool Room and our own in house Tool Makers this allows us to manufacture very quick and simple tooling to reduce cost and speed up parts to our customers to keep cost down during Prototypes stages. This also allows us to be more knowledgeable when the Customer requires the full tooling of their parts.

Etch Tech's tool room is able to provide forming and finishing services, of etched metal component products, including the following:

Aerospace components

Assembly

Deep drawn components

Metal prototypes, components and assemblies

Over moulding

Precision Forming

Sheet metal forming

Soldering

Spot welding including micro spot welding

Tape & reel packaging

Tapping

Tool making + 3D printed tool making

Welding

Wire erosion

Benefits of the Photofabrication Process for Formed Components :

Apertures on both sides as the etchant works on both sides of the metal

Burr & Stress-free manufacturing method

Custom parts – you design it – we make it!

Cost-effective Prototyping

Etch Tech can call on more than 30 years experience in the photo chemical etching of metal components

High Accuracy

Low cost tooling

Industry leading lead times from inception to delivered components

Prototypes – fast turnaround to meet your needs

Scalable through Short Run to High Volume

To find out more about our Photo Etching Process please email, or contact us on 01480 435 548

Get a Fast Track Quote

Tell us about your photo chemical etching requirements today and get a fast track quote. We aim to respond to requests within 4 hours of receipt of your contact, 24 hours guaranteed!