Examples of our work

Door elevation

Our client wanted an impressive, distinctive entrance door that reflected their own professional image. These doors have been surface etched in high detail.

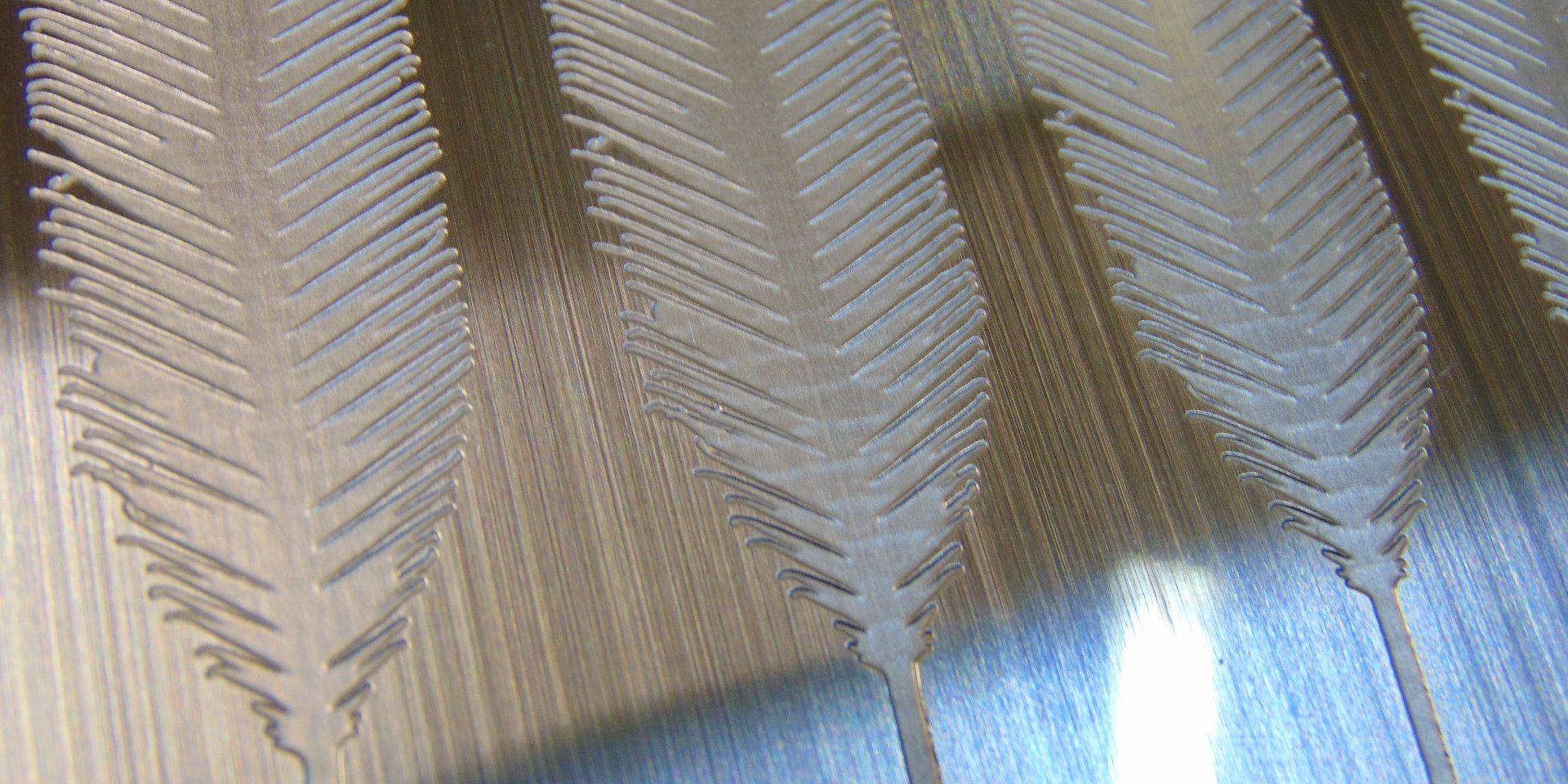

Wembley Stadium

Wembley Stadium is a world-renowned venue and needed a high-quality product. This brushed metal finish has been surface etched with their name and logo

Asos

Asos packaging boxes that look good and show their products to the best effect. Made using the photo chemical etchiNg process, these are polished metal boxes that are different and distinctive.

Brushed aluminium disc

This brushed aluminium disc has been surface etched with black to good effect.

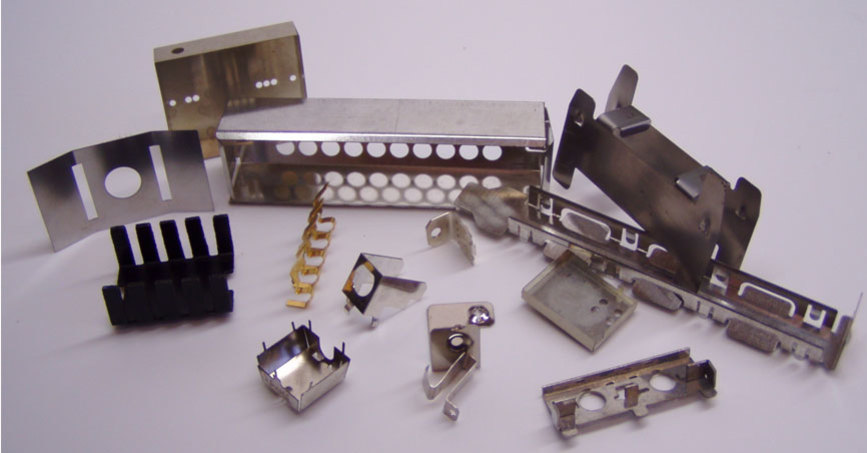

Shielded components

Many of our clients use our etching and forming processes for electronic components. These are for shielded components.

Topshop

This customer needed us to surface etch their company name to their aluminium fabricated rails - a difficult job, but we were happy to help.

Benefits of the Photo Etching Process :

Apertures on both sides as the etchant works on both sides of the metal

Burr & Stress-free manufacturing method

Custom parts – you design it – we make it!

Cost-effective metal component prototyping

Etch Tech can call on more than 30 years experience in the photo chemical etching of metal components

High Accuracy

Low cost tooling

Industry leading lead times from inception to delivered components

Prototypes – fast turnaround to meet your needs

Scalable through Short Run to High Volume

To find out more about our Photo Etching Process please either contact our customer accounts team now

Products Available from Etch Tech Photo Etching Services

Get a Fast Track Quote

Tell us about your photo chemical etching requirements today and get a fast track quote. We aim to respond to requests within 4 hours of receipt of your contact, 24 hours guaranteed!