EMI / RFI Shielding

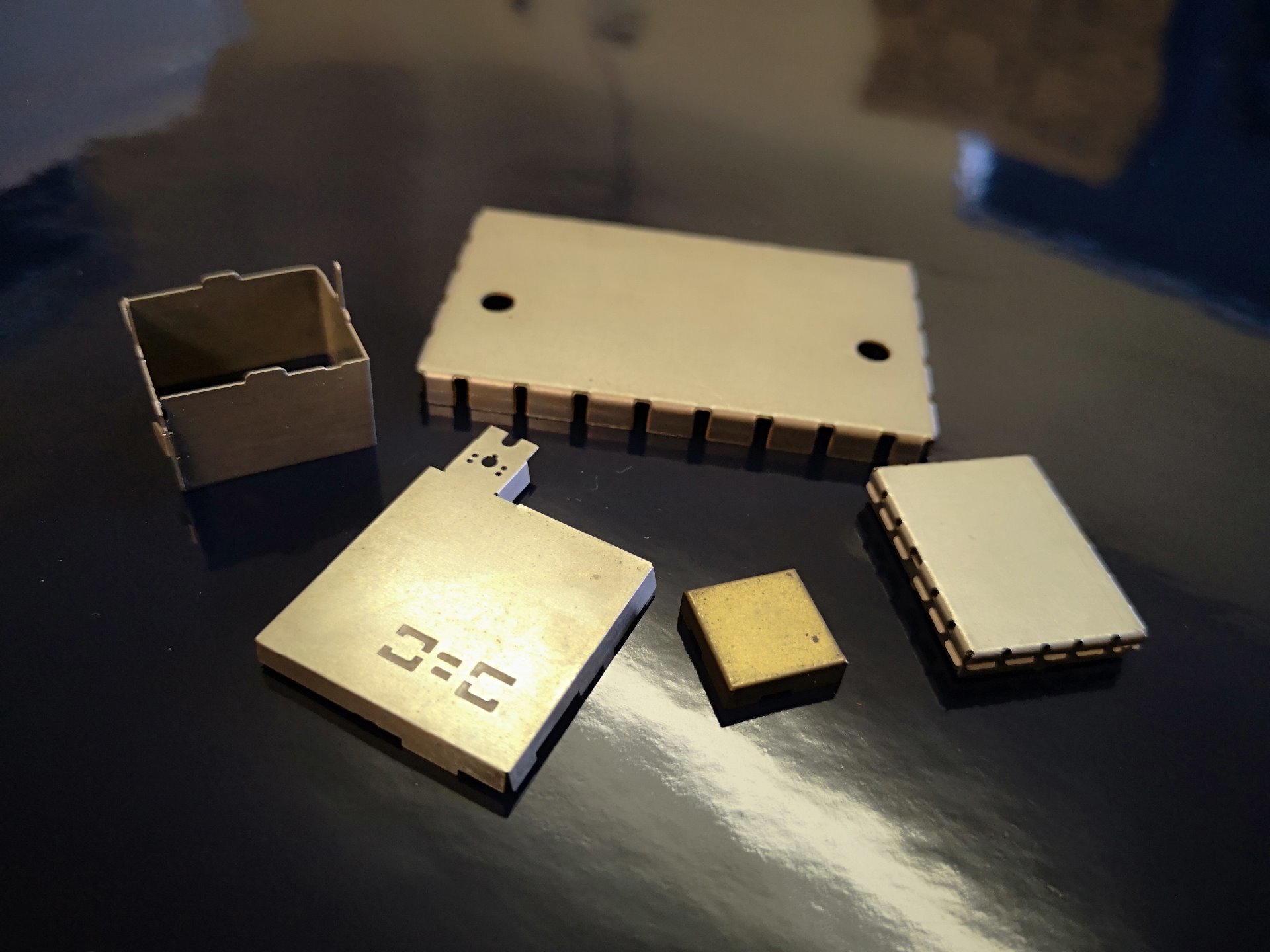

Chemical Milling is well established as an ideal solution for EMC (Electro Magnetic Compatibility) challenges, by providing a quick and cost effective method for Electro Magnetic Interference (EMI) shielding and RFI (Radio Frequency Interference) shielding. We now provide standard sizes of Screening Cans.

GOBOS

GOBOs, or 'Goes Before Optics', are metal discs which, when placed in front of a light-source, control the shape of the light. Etch Tech have extensive experience in the manufacture and supply of chemically etched GOBOs in Aluminium and Stainless Steel.

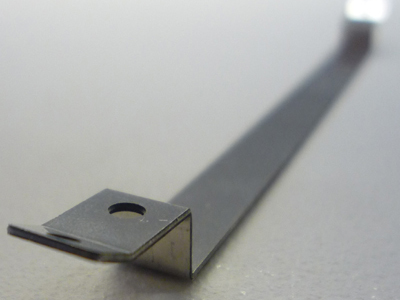

Connectors and Contacts

For the completion of electronic circuits, where a phsyical connection is required, Etch Tech can provide etched metal connectors and contacts. The etching process is perfect for bulk production of components, with forming and plating available for the finishes of parts. This makes Etch Tech the single-source solution for etched connectors and contacts.

Springs - Formed & Flat

Etch Tech can supply chemically etched springs with; heat treating; plating; full assembly giving you a finished spring from from a single supply source. This will reduce your outsource time and therefore reduce product lead times. This allows us and our customers to act more responsively in the face of market demand fluctuations.

Shims & Washers

Photo chemical etching is the perfect solution for high volume production of shims and washers. Stress and burr-free, Etch Tech shims and washers guarantee durability and ease of fit.

Gaskets

Metal gaskets and seals are generally used in inhospitable environments, where other materials would lack durability. As chemical Etching provides burr and stress-free gaskets and seals any Etch Tech customer can feel secure in the longevity and durability of our product.

Fuel Cell Plates

Etch Tech Can manufacture fuel cell plates in Aluminium, Stainless Steel, and Titanium, with a number of finishes, such as Chromium Nitride, available to customers. Whether you require macro, or micro-engineering, Etch Tech can produce fuel cell plates for even miniaturised fuel cells with micro-channels, with a typical depth ratio of 2:1.

Read more

Masks

Etch Tech have significant experience in the photo etching manufacture of masks. We offer evaporation mask plating in either Gold or Rhodium. By doing this we can extend the lifecycle of the mask, by protecting it from acidity in cleaning products.

Read more

Laminations

Etch Tech can call upon more than 30 years of experience in metal laminations. With our electrical steel laminations we provide products that are perfect for winding due to their being burr and stress-free. Etch Tech is able to manufacture and bond stacks of metal laminations (Both E & I), a process which is completely customisable to the requirements of the customer.

Large Panels

With over 30 years of experience, Etch Tech holds a UK leading position due to being uniquely equipped to handle large panels, supplying large panel etched components to areas such as:

Construction

Private Residences

Architectural Design

Retail

Galleries

Artists and Designers

Interior Specialists

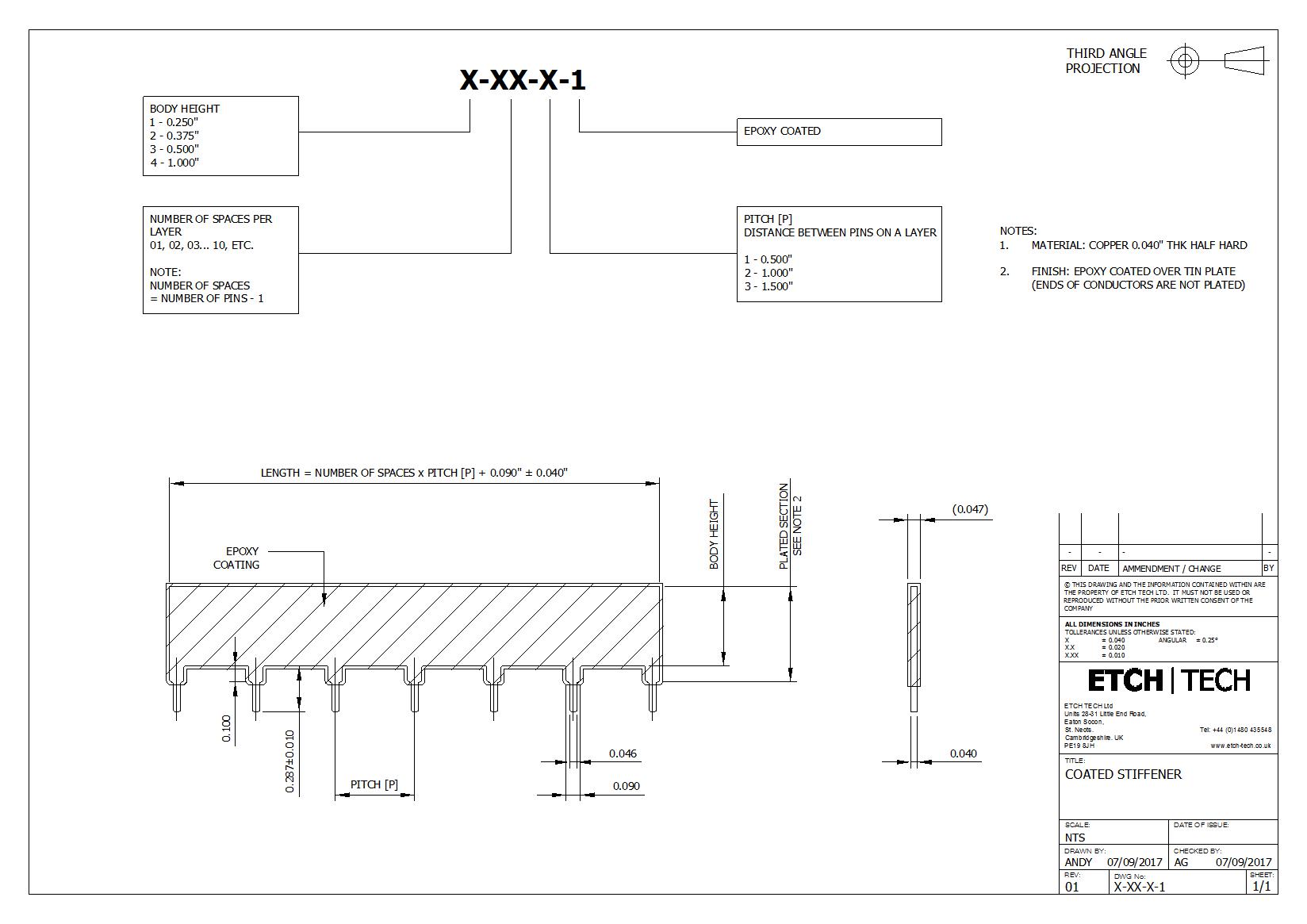

PCB Stiffeners & BusBars

Etch-Tech produce PCB stiffeners & BusBars which are often critical to ensure quality and reliablity during manufacture and assembly of PCB's.

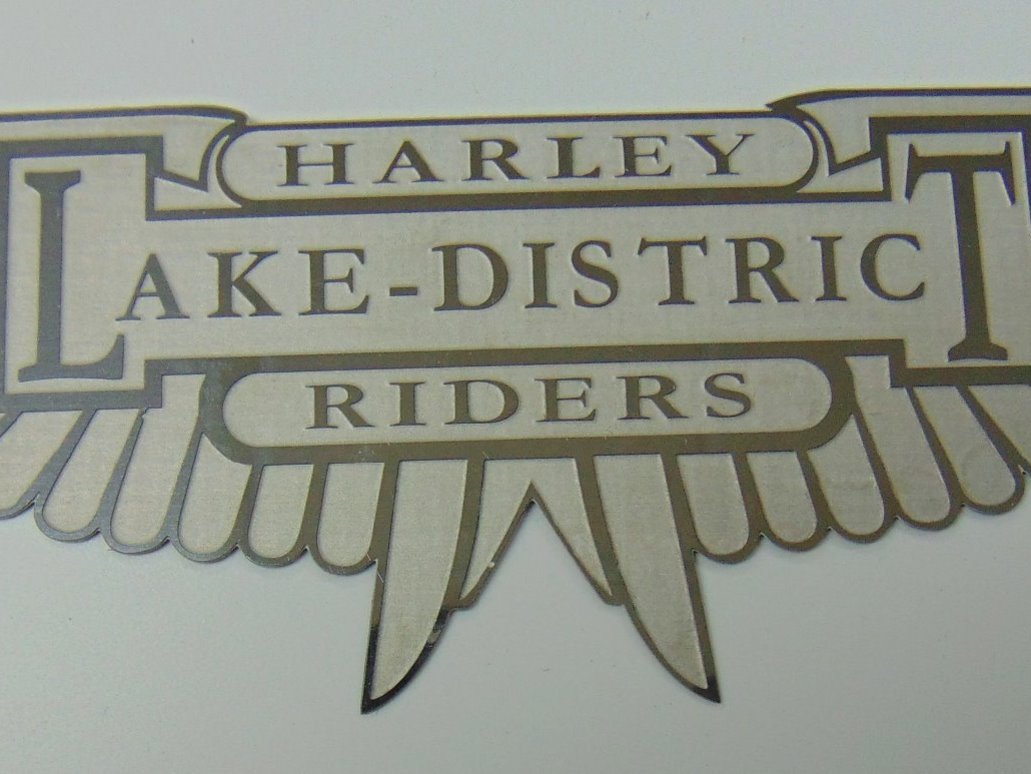

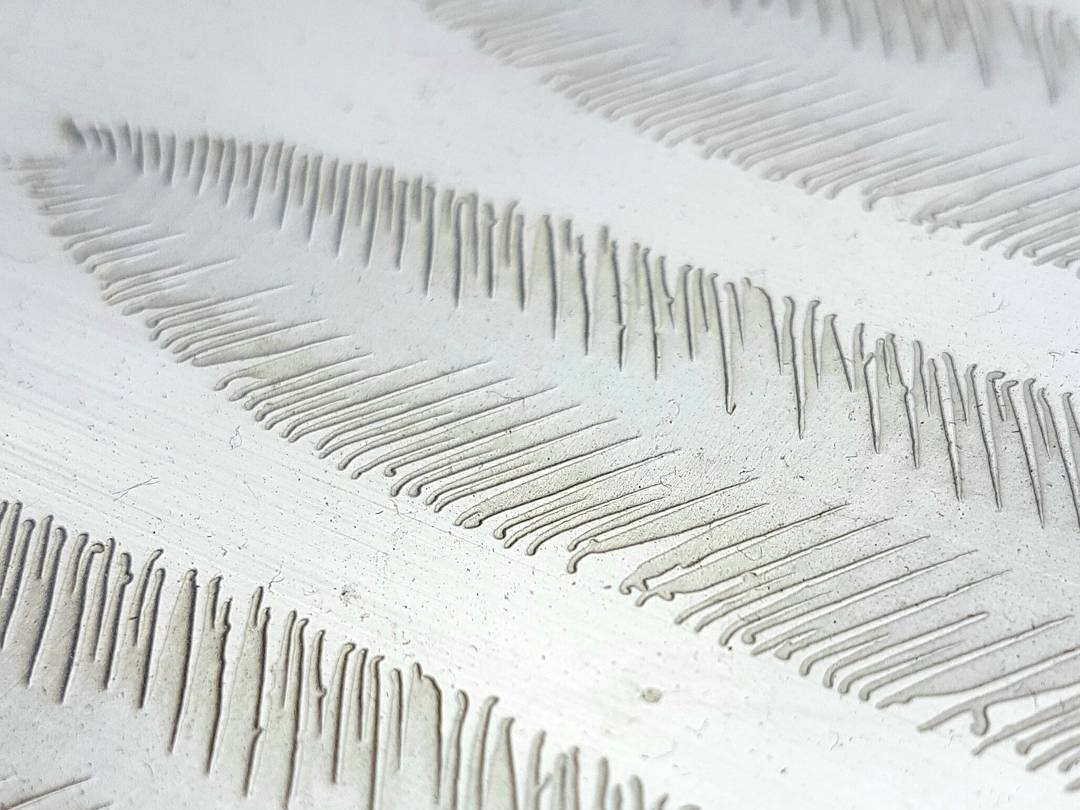

Artwork & Architectural

Architectural metals specialises in the design, fabrication, and installation of architectural components, doors, building facades reception areas, works of art, etc.

Our team of experienced engineers will work closely with owners, architects, contractors, artists and designers, to create bespoke etched installations, and one-of-a-kind masterpieces.

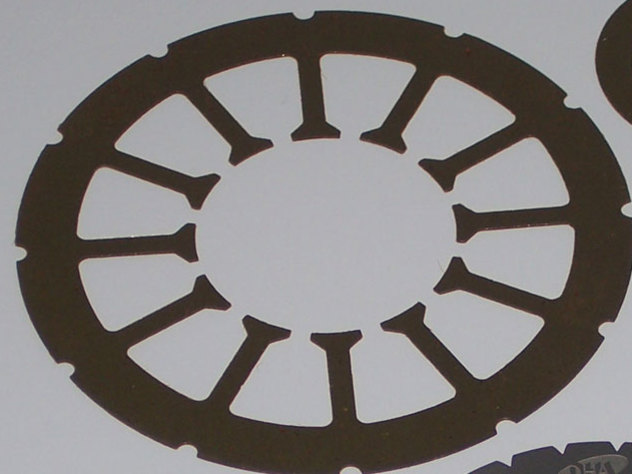

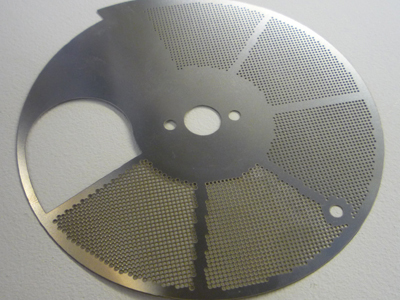

Encoders & Actuators

Etch Tech have significant experience in prototype through to volume production for a vast range of highly-accurate motion control, measurement, and positioning applications. Our chemically etched components are burr and stress free, with an incredibly fine level of precision. Our flexible, single-source production process is fully equipped to handle any requirements and finishes you have for your etched metal Encoder Disks and etched metal Actuators.

Read more

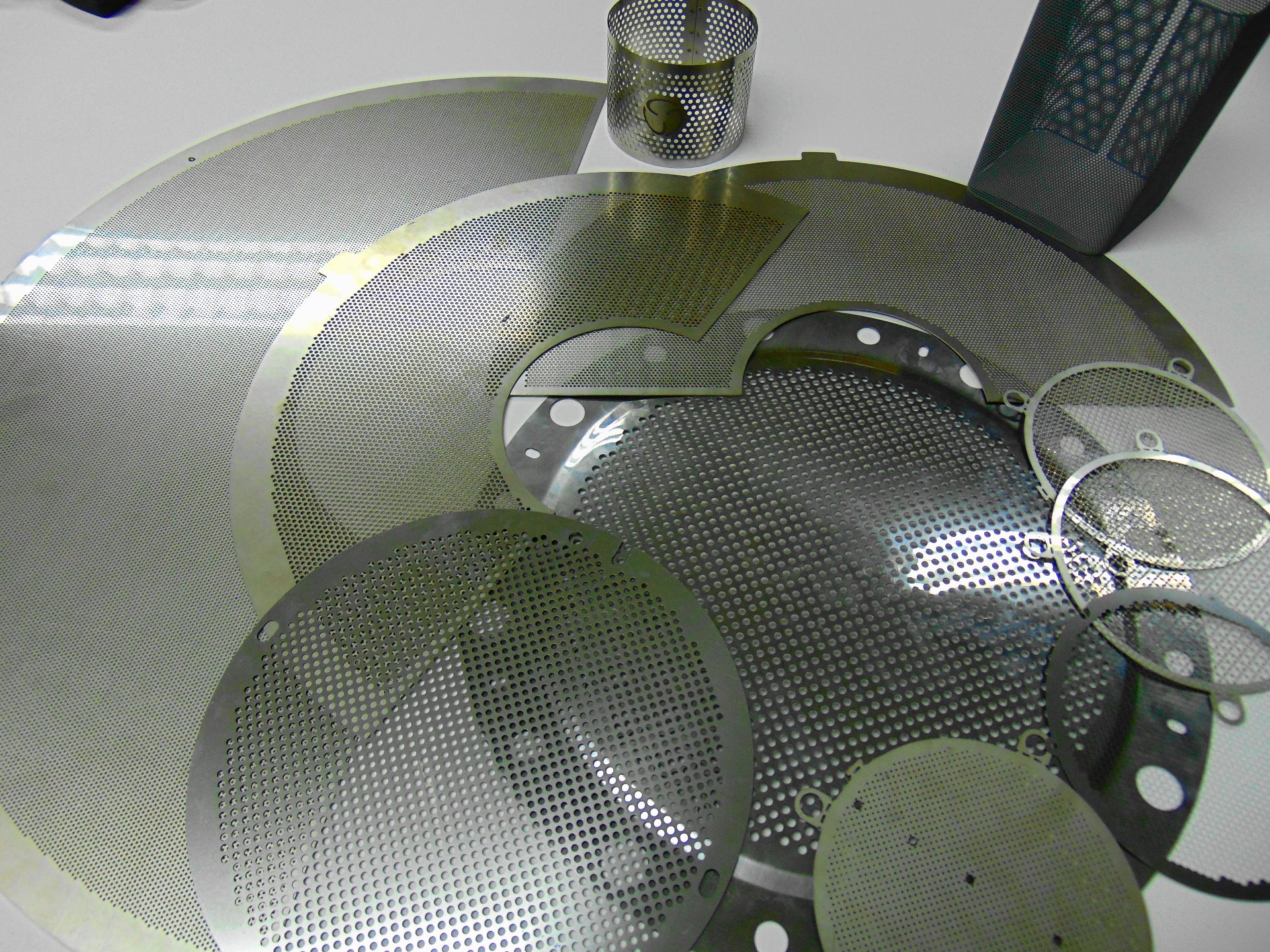

Meshes & Filters

Etch Tech are able to manufacture meshes and filters from a wide range metals, including hardened nickel and stainless steels. Photo etching produces burr and stress free meshes. This results in greater efficiency and material integrity and wouldn't be possible with alternative methods such as punch perforation.

Read more

Etched Artwork

Etch Tech have extensive experience in working with high profile artists and designers from all over the world, providing them with high-quality etched metal products. The Photo Etching process in place at Etch Tech Ltd is capable of etching extremely fine detail into metal. We have extensive experience working closely with customers to offer improved design tolerances on our etched artwork projects. Please contact our design engineers so discuss your requirements.

For any volume of the production of etched metal components, the manufacturing technique of choice is Photo Etching, see below for an in-depth view of the strengths of the process:

Benefits of the Photo Chemical Etching Process :

Apertures on both sides as the etchant works on both sides of the metal

Burr & Stress-free manufacturing method

Custom parts – you design it – we make it!

Cost-effective metal component prototyping

Etch Tech can call on more than 30 years experience in the photo chemical etching of metal components

High Accuracy

Low cost tooling

Industry leading lead times from inception to delivered components

Prototypes – fast turnaround to meet your needs

Scalable through Short Run to High Volume

To find out more about our Photo Etching Process please email, or contact us on 01480 435 548

Get a Fast Track Quote

Tell us about your photo chemical etching requirements today and get a fast track quote. We aim to respond to requests within 4 hours of receipt of your contact, 24 hours guaranteed!