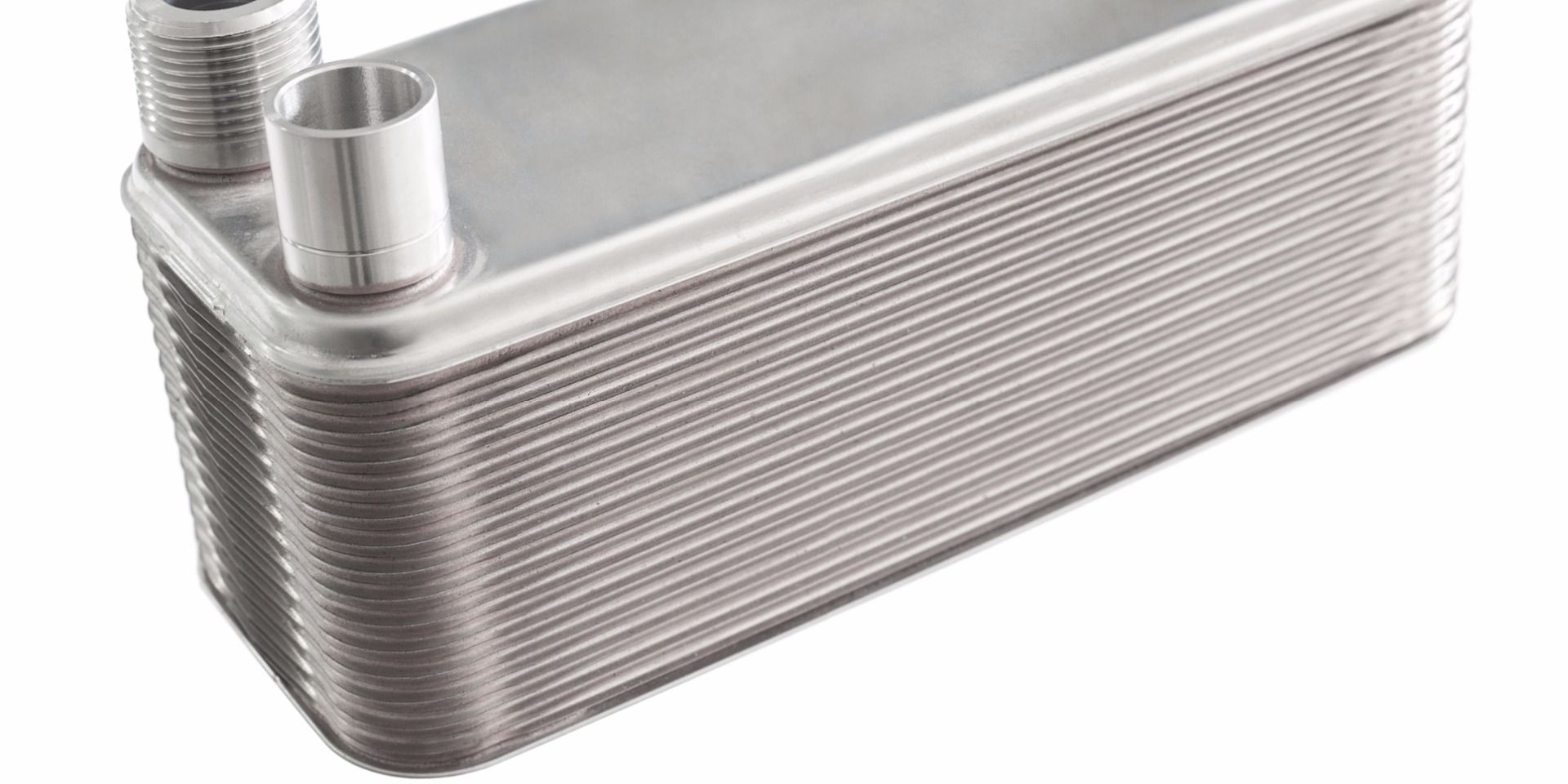

Etch Tech are specialists in the photo etching of plate heat exchangers for the Aerospace, Chemical, Electronics cooling, Linear Motor, and Petrochemical, sectors. A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. The major advantage of this over conventional heat exchangers is that the fluids are exposed to a far larger surface area. This is because the fluids spread out over the heat exchanger plates. Heat exchange plates are manufactured by Etch Tech, utilising the photo etching / chemical milling process, in Aluminium, Inconel, Stainless Steel, and Titanium.

The heat exchangers are manufactured as flat plates with high-precision nano-etched fluid flow channels. These micro-channels can be etched into both sides of the heat exchange plate or, alternatively, just the top surface. It is for this design reason that plate heat exchangers are sometimes referred to as 'Printed Circuit Heat Exchangers' (PCHE’s), due to the manufacturing process being the same as that used for printed circuits.

The plates, having been photo etched / chemically milled, are then stack and either; diffusion bonded; diffusion brazed; or brazed, together in order to make the final heat exchanger product. Utilising the processes of chemical etching and diffusion bonding together, allows for a wide range of construction materials, and therefor a wide range of clean fluids within the heat exchanger product (even corrosive clean fluids).

Etch Tech's finished plate heat exchangers, or cool plates / cooling plates have significant benefits:

Space and weight savings, due to being far smaller than shell, and tube, heat exchangers.

Potential pressure capability of 600 bars (9000 psi)

Temperature durability range from cryogenic to 900°C (1650°F).

More than two process streams can be incorporated in a single unit and the requirement for piping and valve requirements dramatically reduced due to the capacity for more than two process stream to be incorporated with a single plate heat exchanger unit.

Functionality can be increased by the incorpation of mixing and reaction within the design of the plate heat exchanger.

Etch Tech can supply chemically milled metal heat exchangers in the following materials:

Aluminium

Inconel

Stainless Steel

Titanium

Design tolerances

The Photo Etching process in place at Etch Tech Ltd is capable of etching extremely fine detail into metal. We have extensive experience working closely with customers to offer improved design tolerances on our etched metal heat exchangers. Please contact our design engineers so discuss your requirements.