Screen printing

Screen printing is a process that adds graphic detail to a large range of shapes and surfaces be the surface flat, curved or convex.

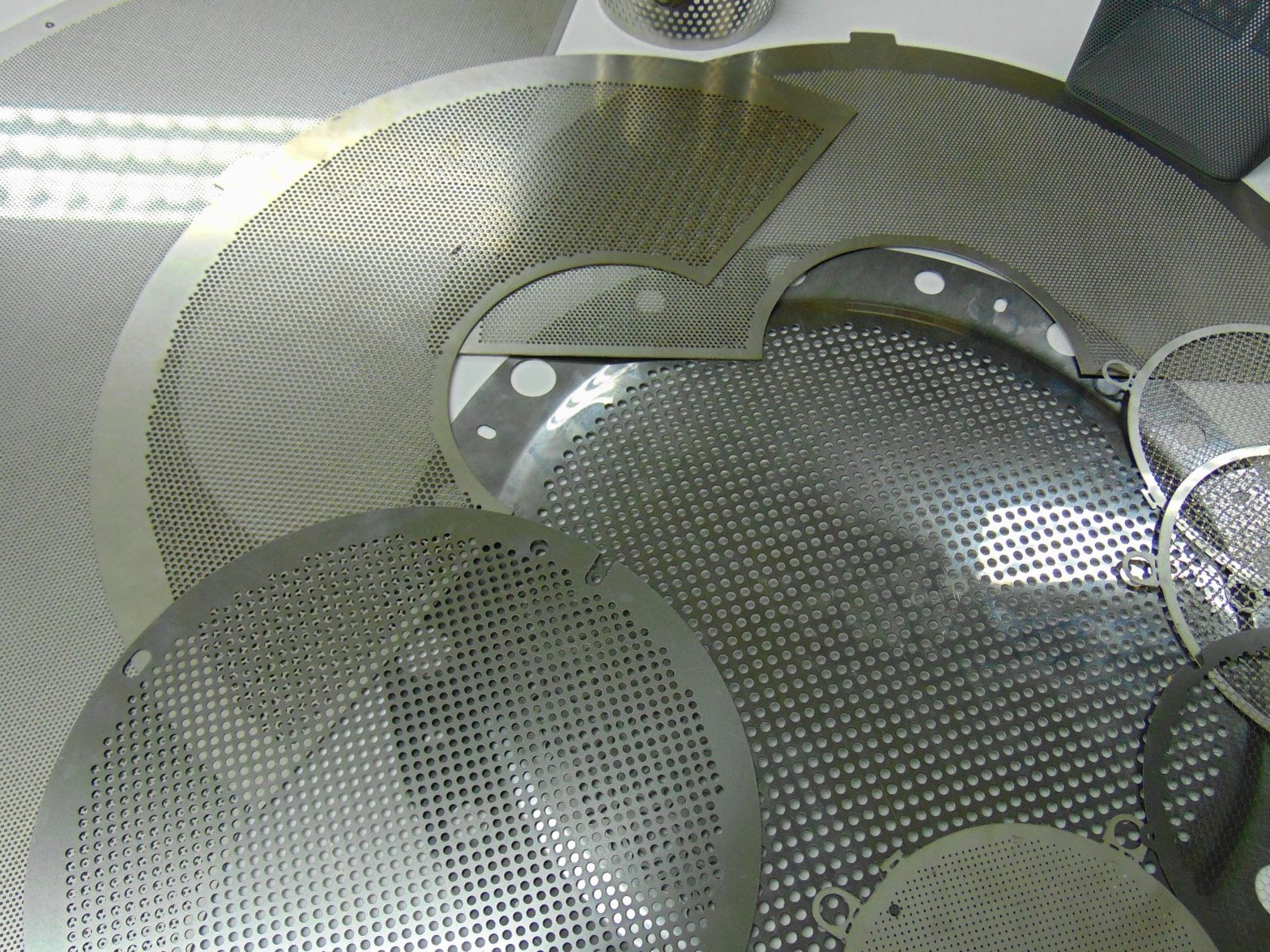

Chemical Milling

Chemical milling is a rapid and flexible precision manufacturing technique offering you the option of very short lead times (from 24hrs), together with batch sizes to suit your build program.

Electronic Files

From receiving the drawing, our design team will work with you to ensure that our etched metal component project is a resounding success. At Etch Tech, we really are with you 'From Inception, to Installation'

Prototyping & High Volume

The flexibility of the photo chemical machining (etching) process means that we are able to transition easily from the prototyping stage to short-run or high volume production. Therefore, Etch Tech is the single-source solution for all your etched metal component requirements.

Large Panels

With over 30 years of experience, Etch Tech holds a UK leading position due to being uniquely equipped to handle large panels, supplying large panel etched components to areas such as:

Construction

Private Residences

Architectural Design

Retail

Galleries

Artists and Designers

Interior Specialists

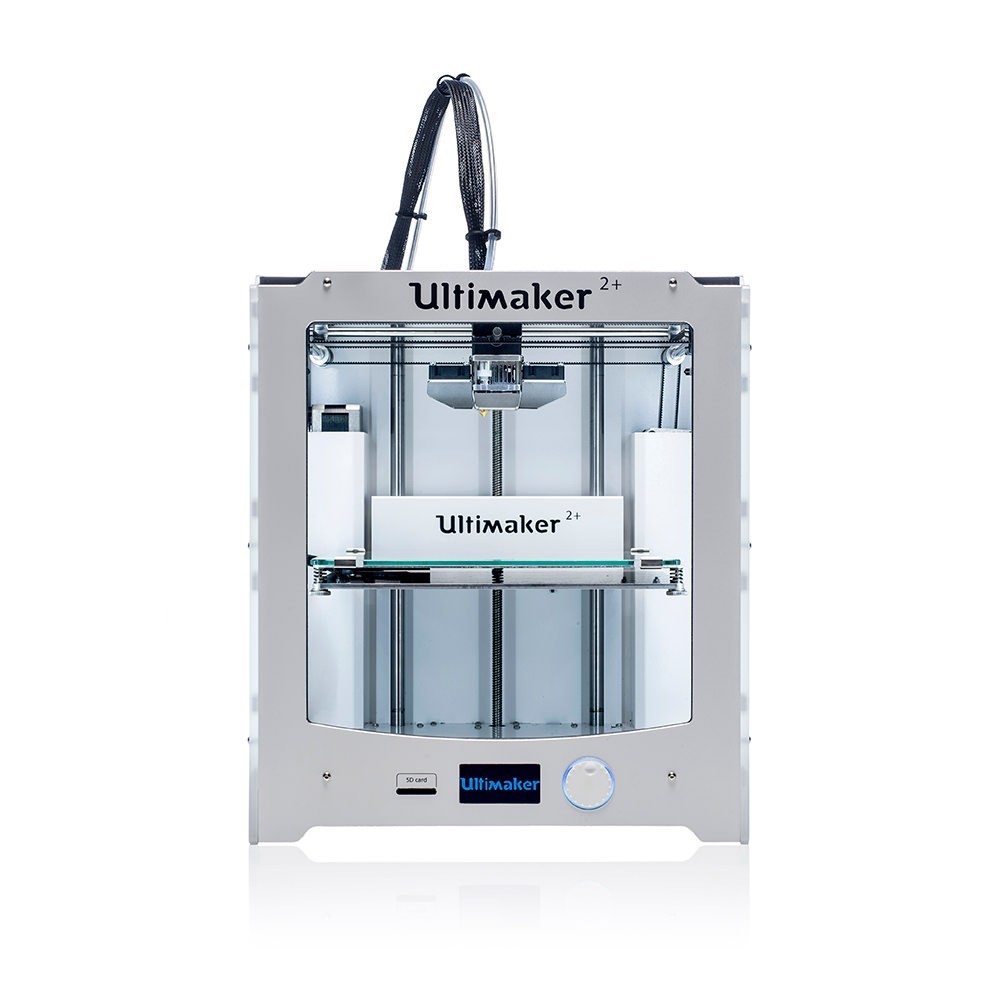

3D Printing

We now provide 3D printing services. When making prototypes you may know that SLS 3D printing is possibly the best way to produce and test your designs. So why not contact us today and turn your ideas into life.

Artwork & Architectural

Architectural metals specialises in the design, fabrication, and installation of architectural components, doors, building facades reception areas, works of art, etc.

Our team of experienced engineers will work closely with owners, architects, contractors, artists and designers, to create bespoke etched installations, and one-of-a-kind masterpieces.

Metal Plating

Etch Tech are able to take care of any plating requirements you have for your etched metal components. Speak to our design consultations about your plating project today.

Read more

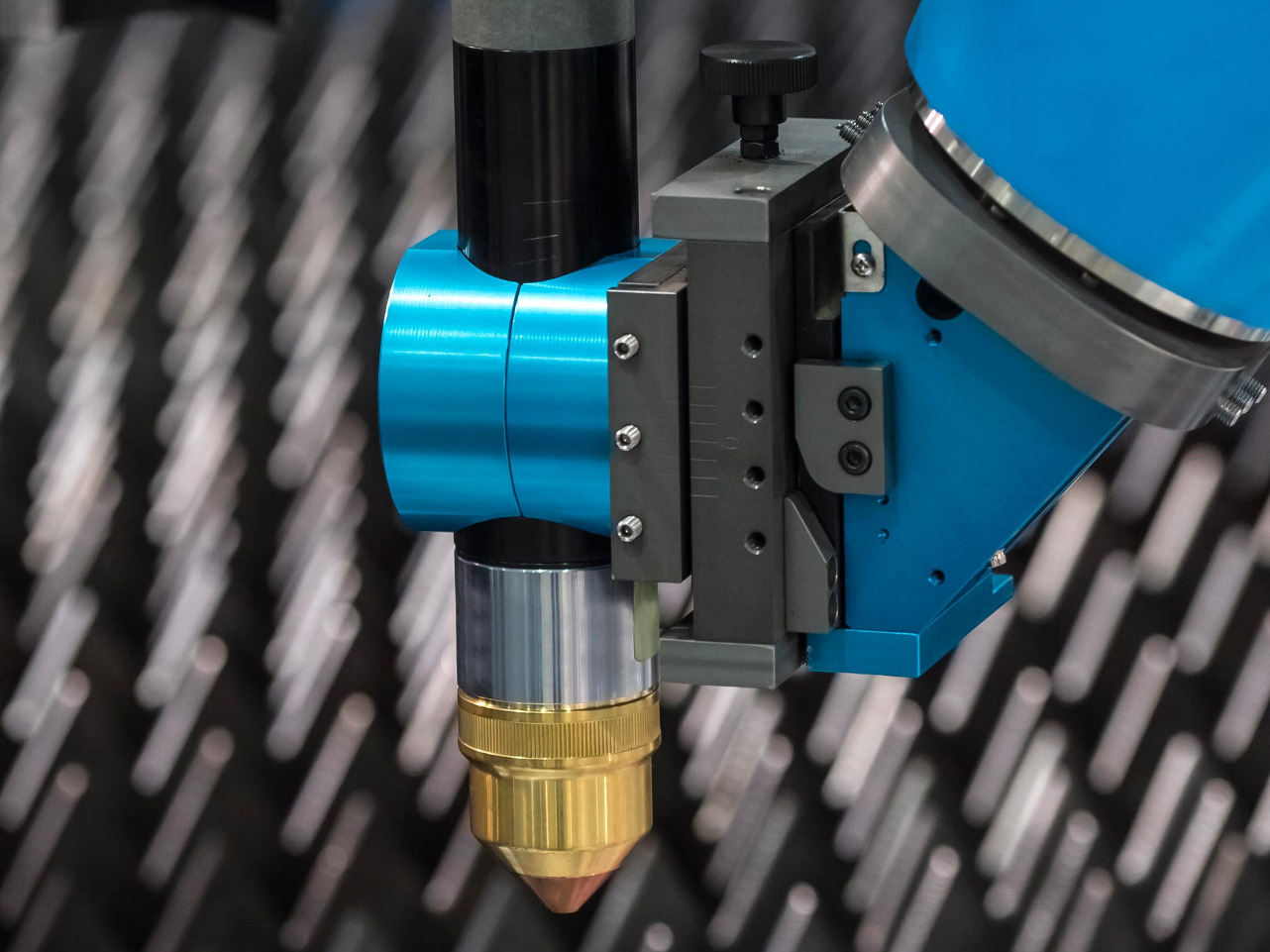

Laser Cutting

Etch-Tech offers a single source solution to all metal component requirements, including Laser Cutting and Chemical Etching.The etching of metal more than 1.5mm thick starts to be less cost-effective. At this juncture laser cutting becomes more economically viable. Etch Tech is able to offer laser cutting services as a single-source solution for precision metal components.

Read more

Project Consultation

At Etch Tech we provide industry-leading customer service. Our design team will always be on-hand to help help make your metal component project a reality. Our design engineers can offer advice, and work with you for the duration of your project - From inception, to Installation!

For any volume of the production of etched metal components the manufacturing technique of choice is Chemical Milling, see below for an in-depth view of the strengths of the process:

Benefits of the Chemical Milling Process :

Apertures on both sides as the etchant works on both sides of the metal

Burr & Stress-free manufacturing method

Custom parts – you design it – we make it!

Cost-effective Prototyping

Etch Tech can call on more than 30 years experience in the photo chemical etching of metal components

High Accuracy

Low cost tooling

Industry leading lead times from inception to delivered components

Prototypes – fast turnaround to meet your needs

Scalable through Short Run to High Volume

To find out more about our Photo Etching Process please email, or contact us on 01480 435 548

Get a Fast Track Quote

Tell us about your photo chemical etching requirements today and get a fast track quote. We aim to respond to requests within 4 hours of receipt of your contact, 24 hours guaranteed!