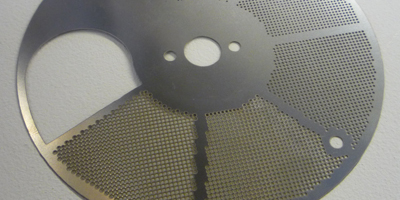

Etch Tech have significant experience in prototype through to volume production for a vast range of highly-accurate motion control, measurement, and positioning applications. Our chemically etched encoder discs and actuators are burr and stress free, with an incredibly fine level of precision. Our flexible, single-source production process is fully equipped to handle any requirements and finishes you have for your encoder discs or actuators.

At Etch Tech we have a wealth of experience in the manufacture of encoder discs with extremely small slot resolution (line widths from 0.004 in. [0.10 mm], in a wide range of thicknesses dependent on the specifications of the encoder, as set by the customer. Etch Tech makes phototools in-house, and manufactures in the photochemical etching process, meaning that we can manufacture high precision optical encoders. Furthermore, due to the precision of the process, we guarantee exact slot repetition from one slot to the next, as well as a stress and burr-free encoder disc or actuator. Component tolerances are typically held within 10% of material thickness.

Etch Tech can supply Photo Chemically Etched metal encoder discs and actuators in the following materials:

Berillyium Copper

Nickel

Stainless Steel

And many more, please contact our engineers for more information.

Design tolerances

The Photo Etching process in place at Etch Tech Ltd is capable of etching extremely fine detail into metal. We have extensive experience working closely with customers to offer improved design tolerances on our encoder discs and actuators. Please contact our design engineers so discuss your requirements.