Signage, Gift ware, Decorative, and Model Engineering

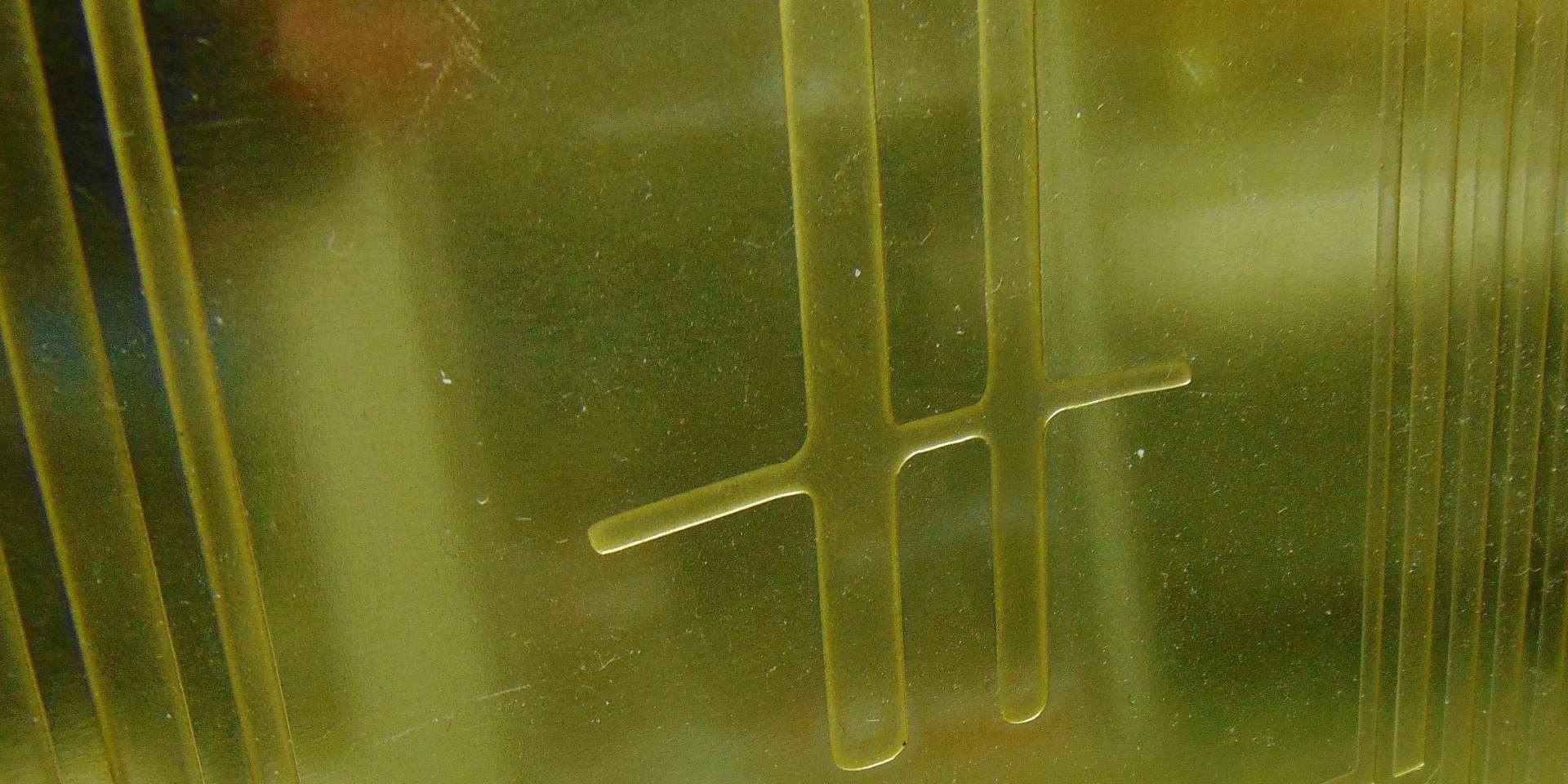

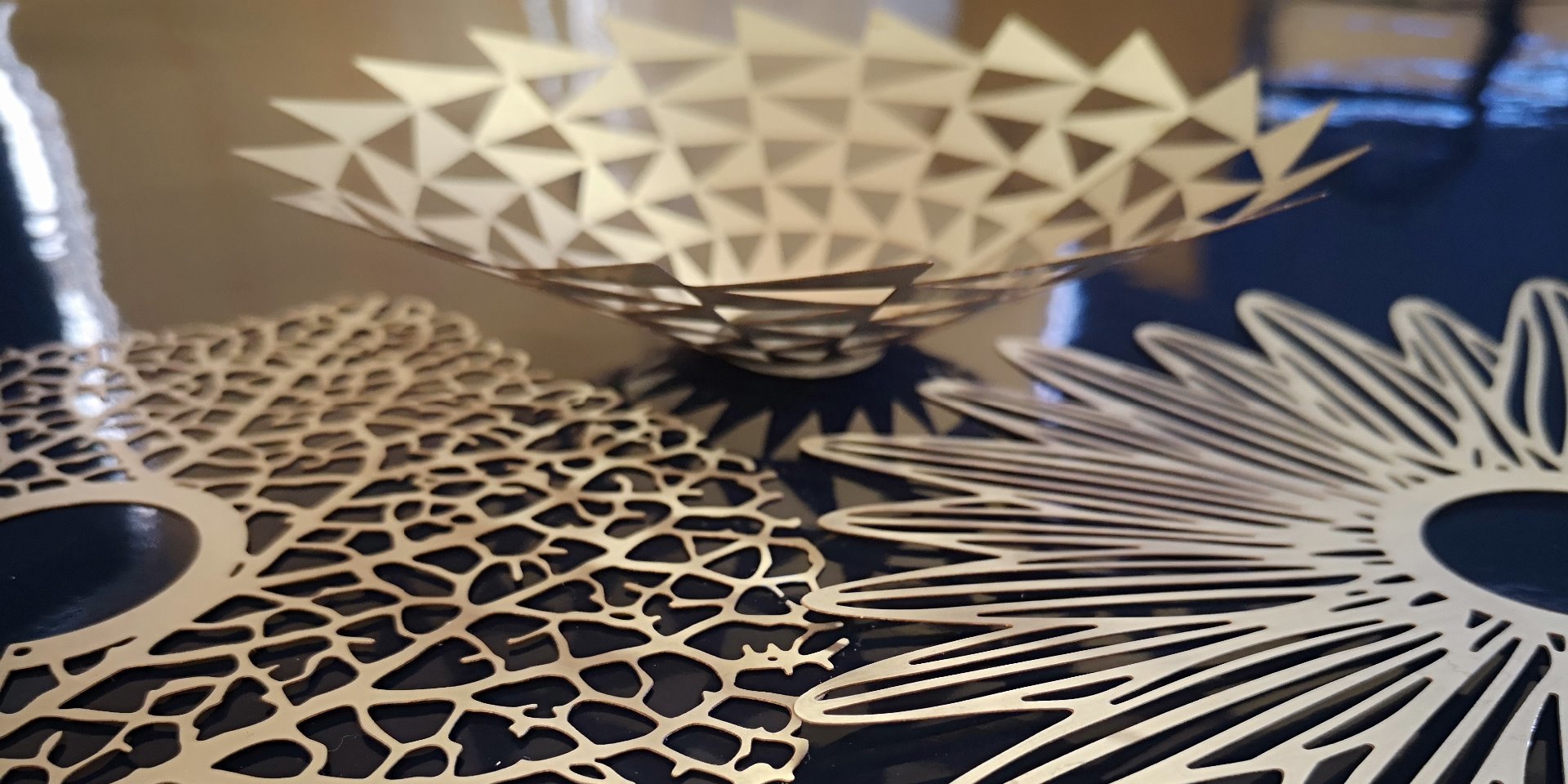

A feature of Chemical Milling which is difficult and expensive to replicate by any other manufacturing technique, is the ability to etch complex surface detail to a high degree of accuracy. The potential of this process was quickly realised for use in metal signage followed very rapidly by other applications which require surface detail in relief.

Etch Tech have a wealth of experience in producing items ranging from 2.5mtr long signs through to the most delicate frets of model parts. Our skilled graphics department team can design for you, or use your supplied design. Your designs can be supplied as 'clean etched' items or with paint infill to your colour specification.

Only the highest quality

Etch Tech have developed an advanced process which allows the surface etching of curved surfaces and other complex shapes that in the past have proved too difficult. This technique was recently used to etch a well known high street logo onto stainless steel clothing racks after they had been fully assembled and welded.

Etched brass components have long been the mainstay of model trains and boats and whilst the bulk of this type of work is supplied to retail specialists (we may have etched your favourite kit!), Etch Tech are pleased to take commissions from modellers involved in unique projects. Our experienced designers will be able to assist you with your requirements.

Typical metal products which are manufactured by Chemical Milling include:

Signs and Plaques

Invitations

Novelty Items

Model Trains

Model Boats

Retail Displays

Architectural Metalwork

Architectural Models

Your requirements are important to us; you are guaranteed a first class service when you specify Etch Tech as your manufacturing partner.

Etch Tech can supply a range of Photo Chemically Etched decorative products, such as:

Advertising Products

Bespoke Artwork

Clock Dials

Decorative Metal Lighting Installations

Facia Panels

Fold-up Dioramas

Gift Boxes

Gobos

Insignia

Labels

Large Panels

Logos

Luxury Packaging

Nameplates

Name Cards

Paper cutter blanks

Personalised Dog tags

Personalised Metal Business Cards

Presentation plaques

Speaker grilles

Wedding invitations

Design tolerances

The Photo Etching process in place at Etch Tech Ltd is capable of etching extremely fine detail into metal. We have extensive experience working closely with customers to offer improved design tolerances on our decorative products. Please contact our design engineers so discuss your requirements.

For any volume of the production of Decorative Components and Installations, the manufacturing technique of choice is Chemical Machining, see below for an in-depth view of the strengths of the process:

Benefits of the Chemical Machining Process :

Apertures on both sides as the etchant works on both sides of the metal

Burr & Stress-free manufacturing method

Custom parts – you design it – we make it!

Cost-effective Prototyping

Etch Tech can call on more than 30 years experience in the photo chemical etching of metal components

High Accuracy

Low cost tooling

Industry leading lead times from inception to delivered components

Prototypes – fast turnaround to meet your needs

Scalable through Short Run to High Volume

To find out more about our Photo Etching Process please email, or contact us on 01480 435 548

Get a Fast Track Quote

Tell us about your photo chemical etching requirements today and get a fast track quote. We aim to respond to requests within 4 hours of receipt of your contact, 24 hours guaranteed!