EMI Shielding & RFI Shielding

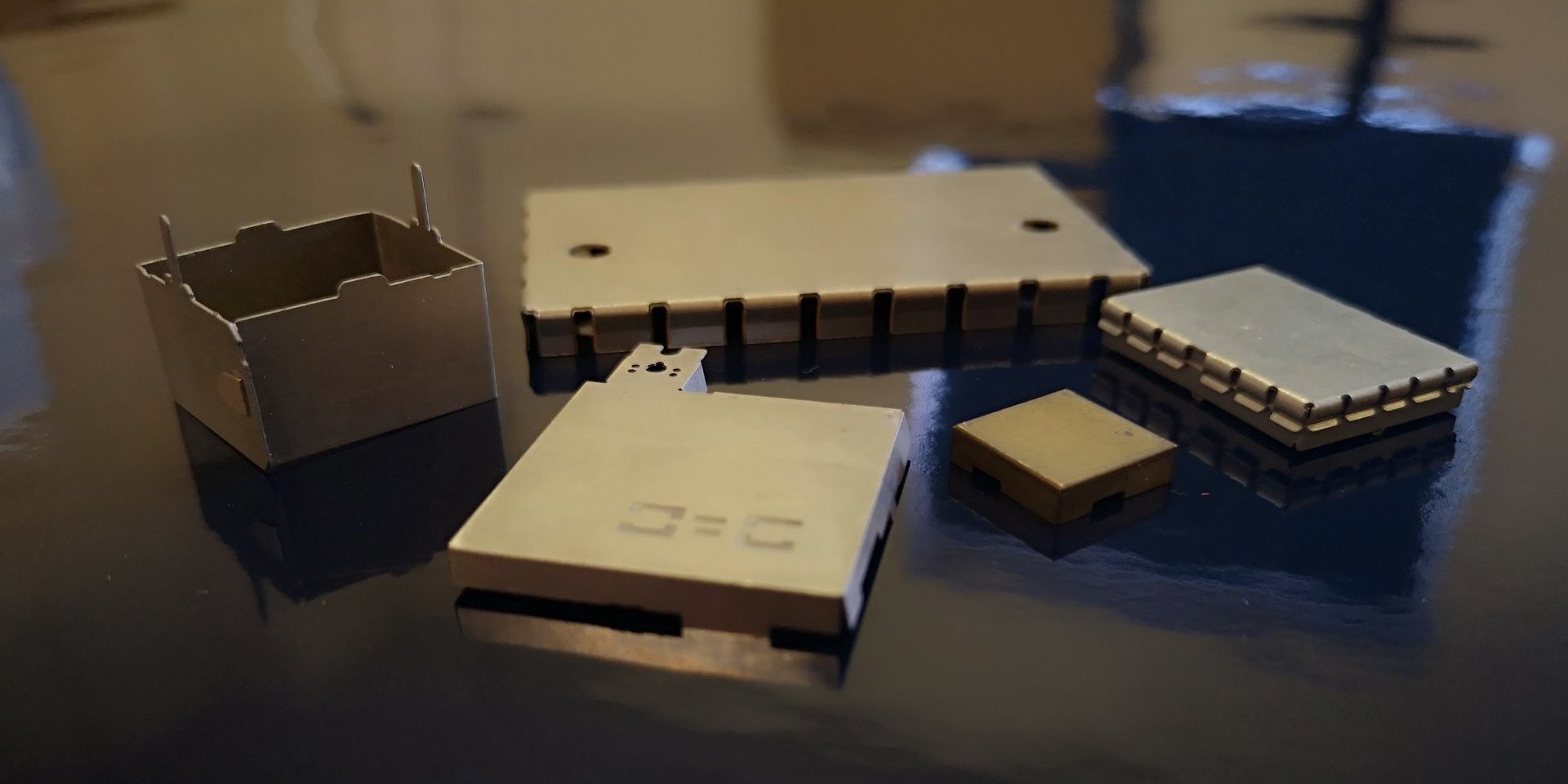

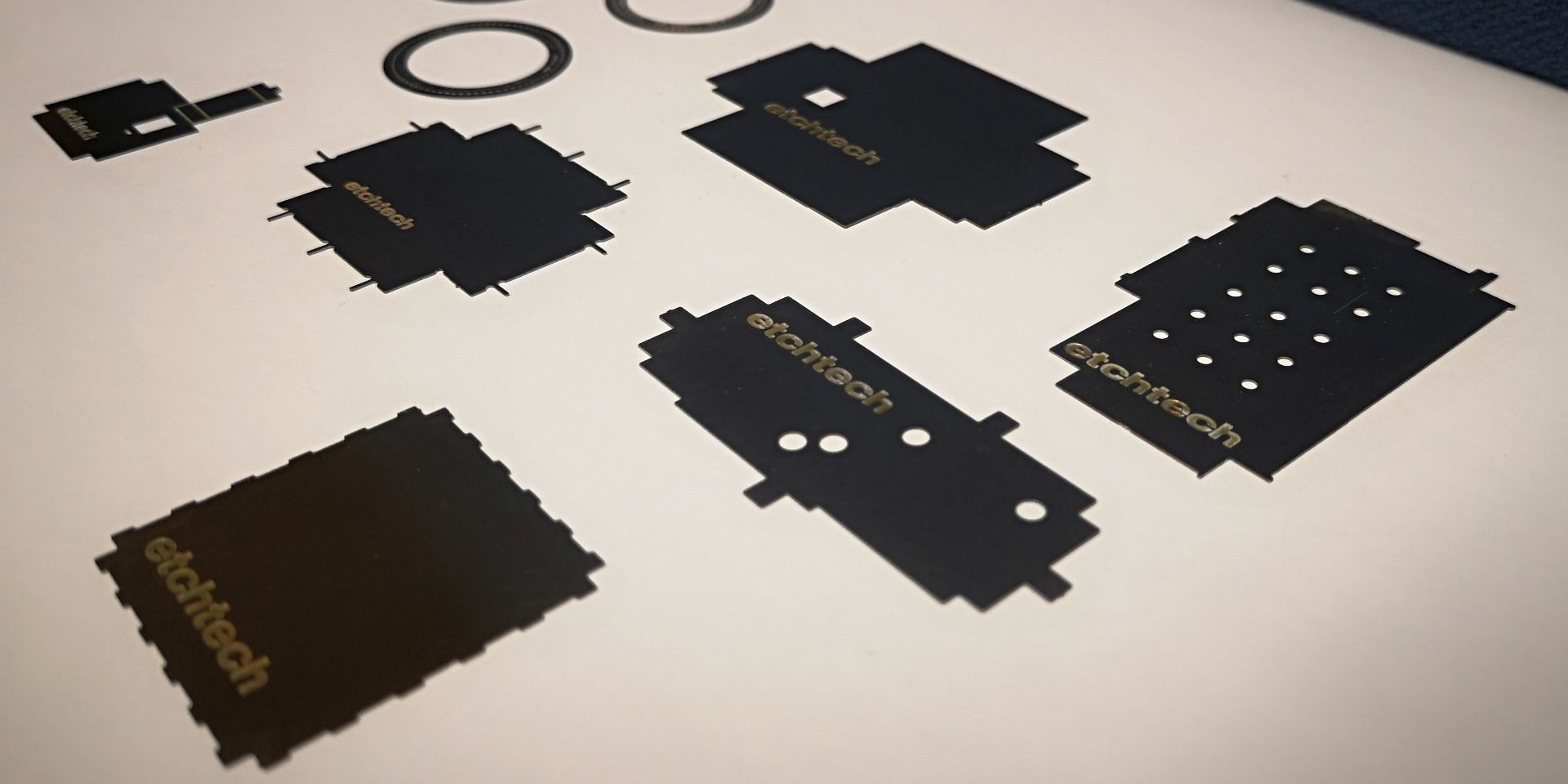

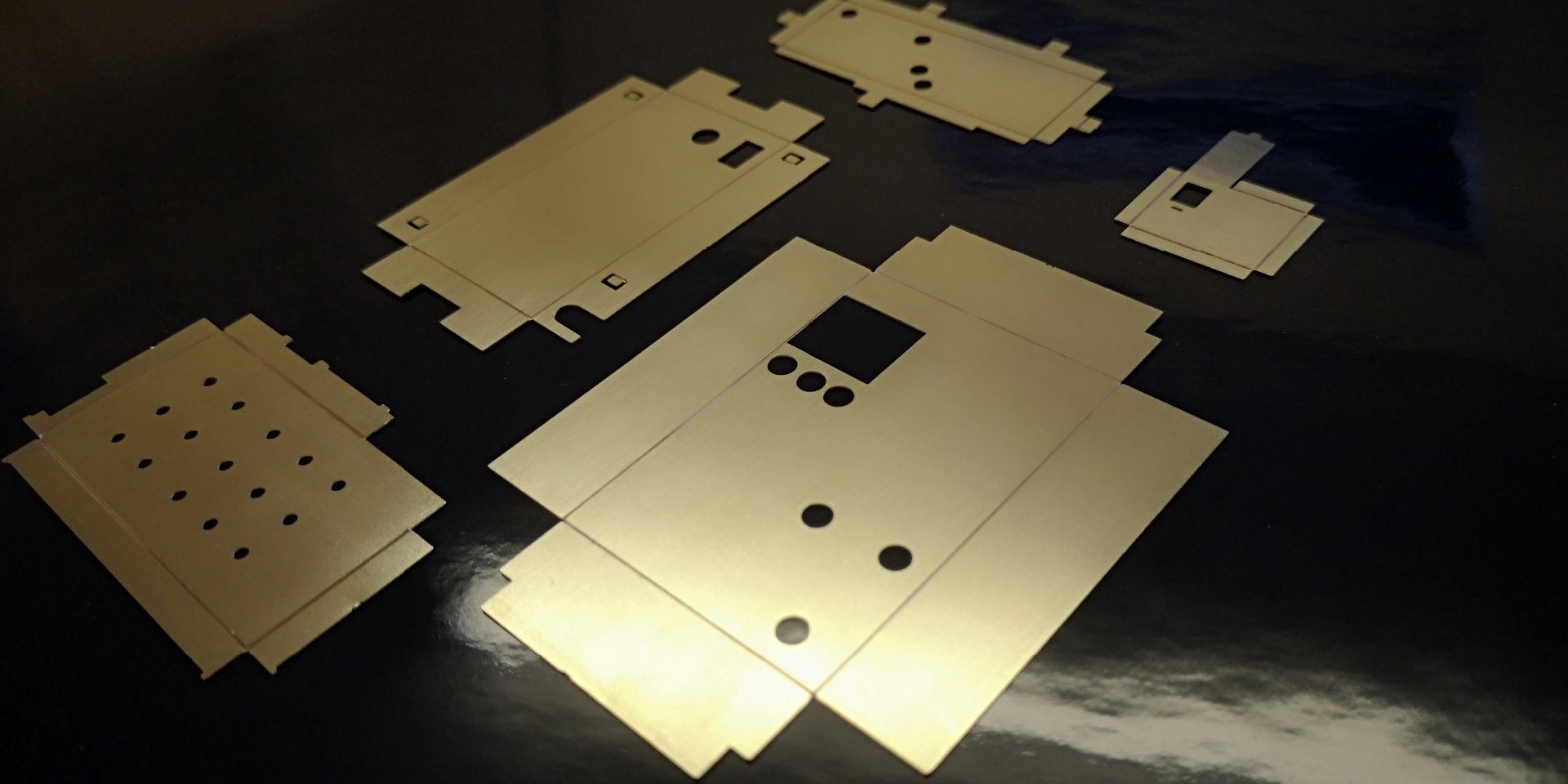

Chemical Milling is well established as an ideal solution for EMC (Electro Magnetic Compatibility) challenges, by providing a quick and cost effective method for Electro Magnetic Interference (EMI) shielding and RFI (Radio Frequency Interference) shielding.

Cost effective specific designs

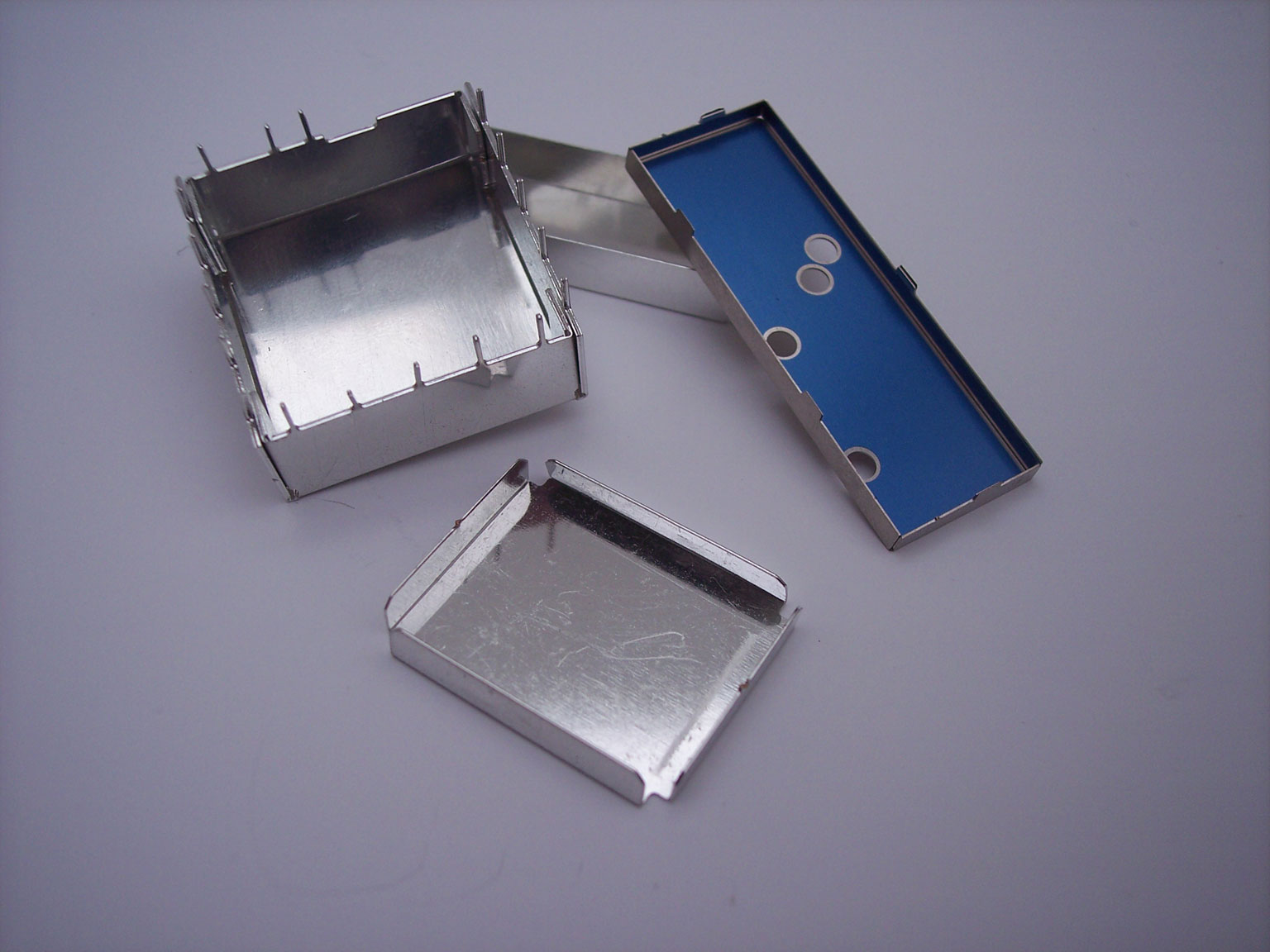

Etch Tech provide cost effective specific designs in very short time scales, so board level shielding does not have to be compromised by the use of "standard of the shelf" products. We can work to exact requirements, for example single piece cans, two part fence and lid designs, tear off lids or multi compartment types. All are available in “through hole” or “surface mount” variations.

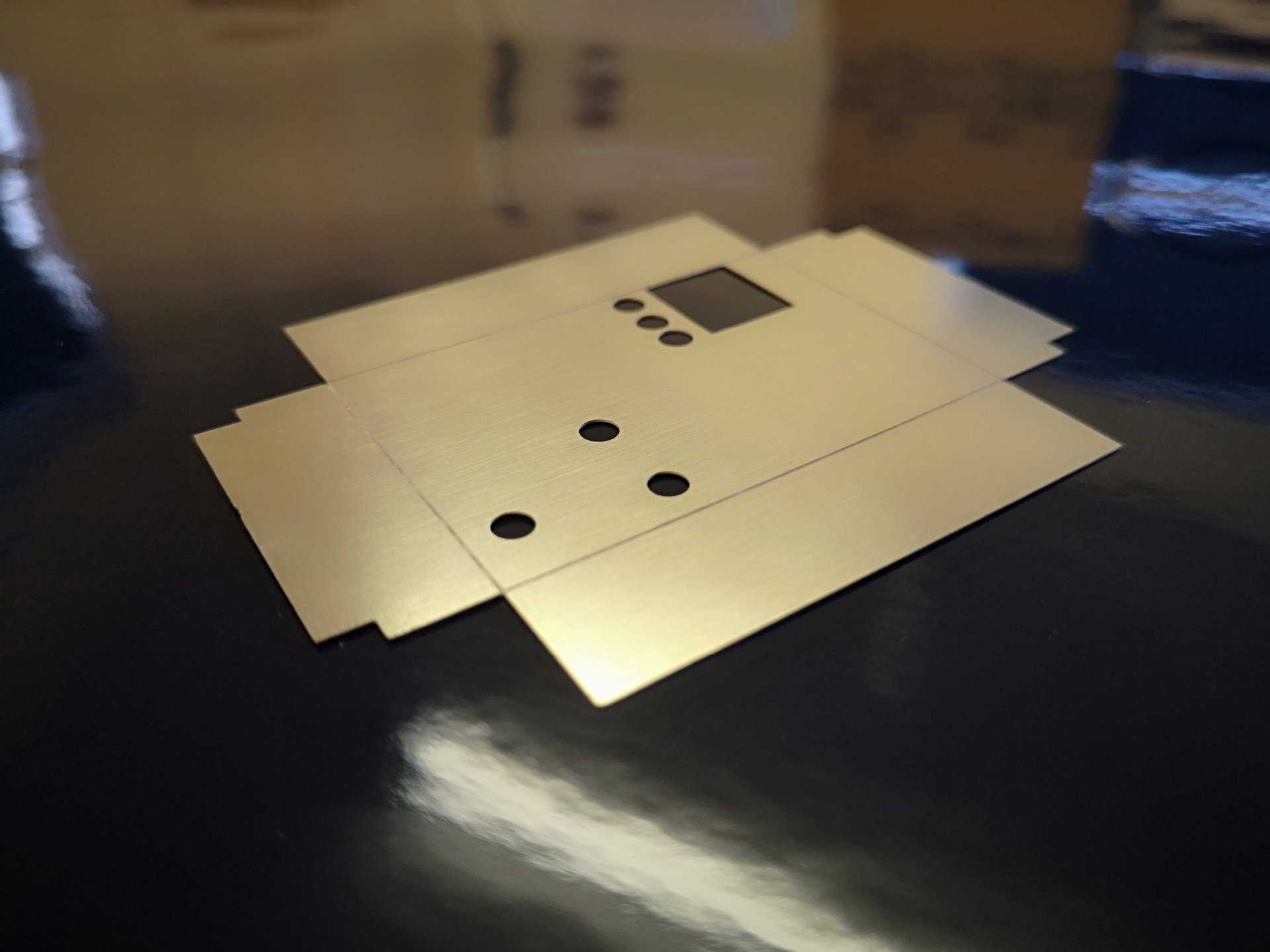

We can also surface etch the part number or company logo on to the part at no extra cost. The same Etch Tech technology used to produce the identification marks can also be utilised to surface etch "folding lines" , allowing the screens to be formed without the need for expensive form tooling. This saves costs and also enables parts to be supplied flat for hand folding at your chosen manufacturing site or supplied as fully formed items.

You can specify your base metal, including Nickel Silver, Copper, Copper Alloys, Mild Steel, Stainless Steel and Mu Metal (Hymu 80) either plated or in the natural state.

Prosafe insulation - a unique solution to insulation

Where size constraints limit the size of shielding used, Etch Tech have developed the 'Prosafe' system which allows either selective or total insulation of the specified surfaces or areas. Our sales team are always available to discuss your requirement in full either at design stage or further along the development process when it becomes apparent additional insulation is required. Please see picture above, the blue layer is where the 'prosafe' system has been applied to prevent components from shorting out.

Whilst enclosures and board level screening account for the majority EMI/RFI Photo Etched products, Etch Tech are equally experienced in manufacturing contact strips (finger strips) usually from Beryllium Copper or Phosphor Bronze.

Etch Tech are happy to discuss your exact requirements for prototype through to production quantities, either by telephone or at your preferred location. We are able to accept your drawings as electronic files, including dxf, dwg, SolidWorks, STEP, IGES, ProEngineer and PDF. We can also work from your dimensioned hard copy drawings.

We Now Provide Standard Sized Screening Cans

We have many variations of standard screening cans available to our clients please click to the right to see more.

Etch Tech can supply Photofabricated metal EMI & RFI Shielding in the following materials:

Aluminium

Beryllium Copper

Brass

Copper

Molybdenum

Mu-Metal

Nickel Silver

Phosphor Bronze

Radio-Metals

Stainless Steel

Steel

Titanium Alloy

Design tolerances

The Photo Etching process in place at Etch Tech Ltd is capable of etching extremely fine detail into metal. We have extensive experience working closely with customers to offer improved design tolerances on our EMI / RFI Shielding. Please contact our design engineers so discuss your requirements.

For any volume of the production of EMI & RFI Shielding, the manufacturing technique of choice is the Photofabrication process, see below for an in-depth view of the strengths of the process:

Benefits of the Photofabrication Process :

Apertures on both sides as the etchant works on both sides of the metal

Burr & Stress-free manufacturing method

Custom parts – you design it – we make it!

Cost-effective metal component prototyping

Etch Tech can call on more than 30 years experience in the photo chemical etching of metal components

High Accuracy

Low cost tooling

Industry leading lead times from inception to delivered components

Prototypes – fast turnaround to meet your needs

Scalable through Short Run to High Volume

To find out more about our Photo Etching Process please email, or contact us on 01480 435 548

Get a Fast Track Quote

Tell us about your photo chemical etching requirements today and get a fast track quote. We aim to respond to requests within 4 hours of receipt of your contact, 24 hours guaranteed!